Synoptic

General concept of flue gas cleanup

DOC

Oxydation catalyst

DOC promotes oxidation of toxic particulates at low temperature from 200°C

HC (60 – 80%)

CO (> 80%)

Soluble particulates -SOF (40 – 60%) / Total particulates(10 – 40%)

NO -> NO2 (helping to reduce the T° combustion of the soot trapped in the DPF)

DPF

Diesel Particulate Filter

A diesel particulate filter is a honeycomb made from extruded ceramic (cordierite or silicon carbide). The channels of the honeycomb are blocked alternately at the input and output of the filter to force the passage of gas through the porous walls and retaining soot and solid compounds present in the exhaust gas flow.

The efficiency is higher than 95%.

The cleaning of the filter (regeneration) is obtained by increasing the gas temperature for promoting the oxidation of the soot trapped in the filter (thermally, or by catalytic chemical reaction with NO2 as explained earlier).

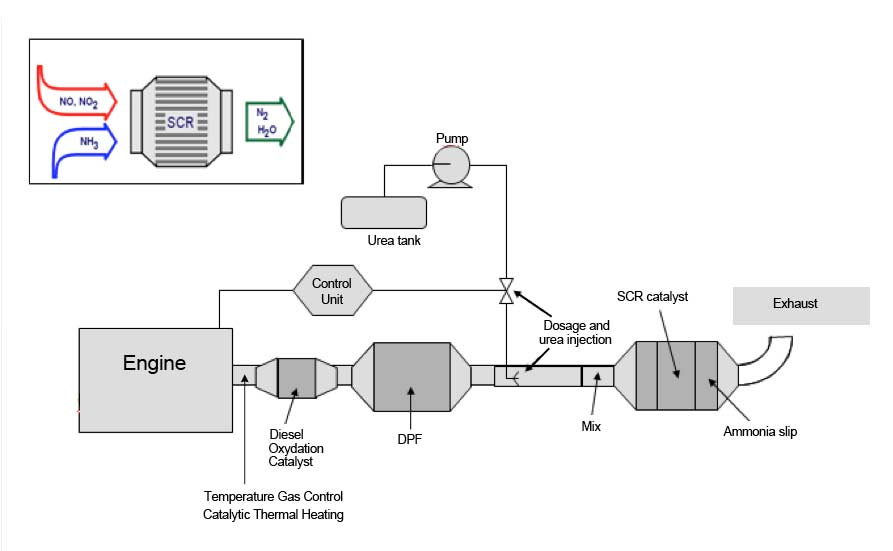

SCR

Selective Catalyst Reduction of nitrogen oxides

This process converts NOx into N2 and water. This conversion is achievable by injecting a reductant agent (urea, ammonia) in front of the catalyst.

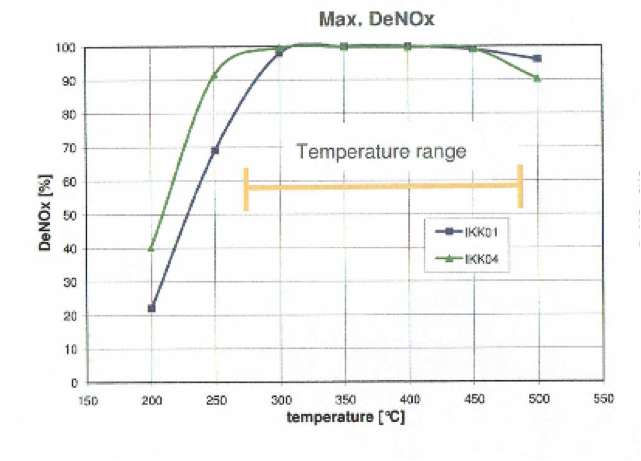

Higher efficiency than 95% is obtained through a temperature range from 280 to 450°C.

The dosage of urea, injection, mixing and uniform watering in the inlet section of the catalyst are part of the expertise of SEVNOX to ensure high efficiency.

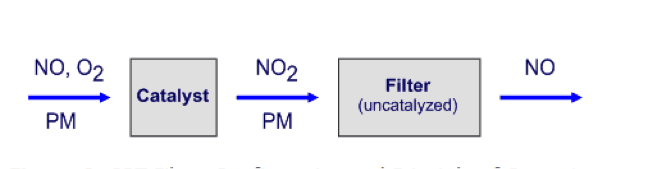

Continuous regeneration of the filter

Below the diagram of the process of continuous regeneration by reaction of soot trapped on the filter with NO2 produced on the catalyst.